Automated Spill Containment Solutions

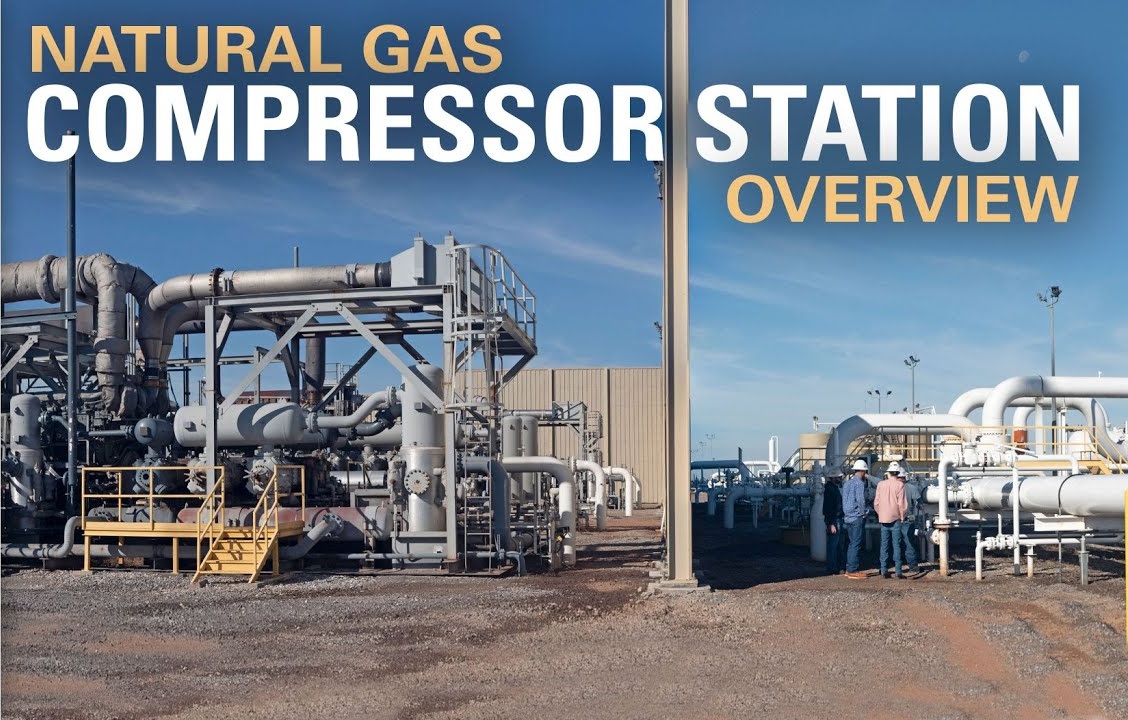

Automated Spill Containment for Natural Gas Compression & Pipeline Operations

40+ Years Combined Compressor & Oilfield Pipeline Experience

Automated Spill Containment for Natural Gas Compression & Pipeline Operations

40+ Years Combined Compressor & Oilfield Pipeline Experience

Browse our products below, then learn how they eliminate manual pumping and keep you compliant 24/7

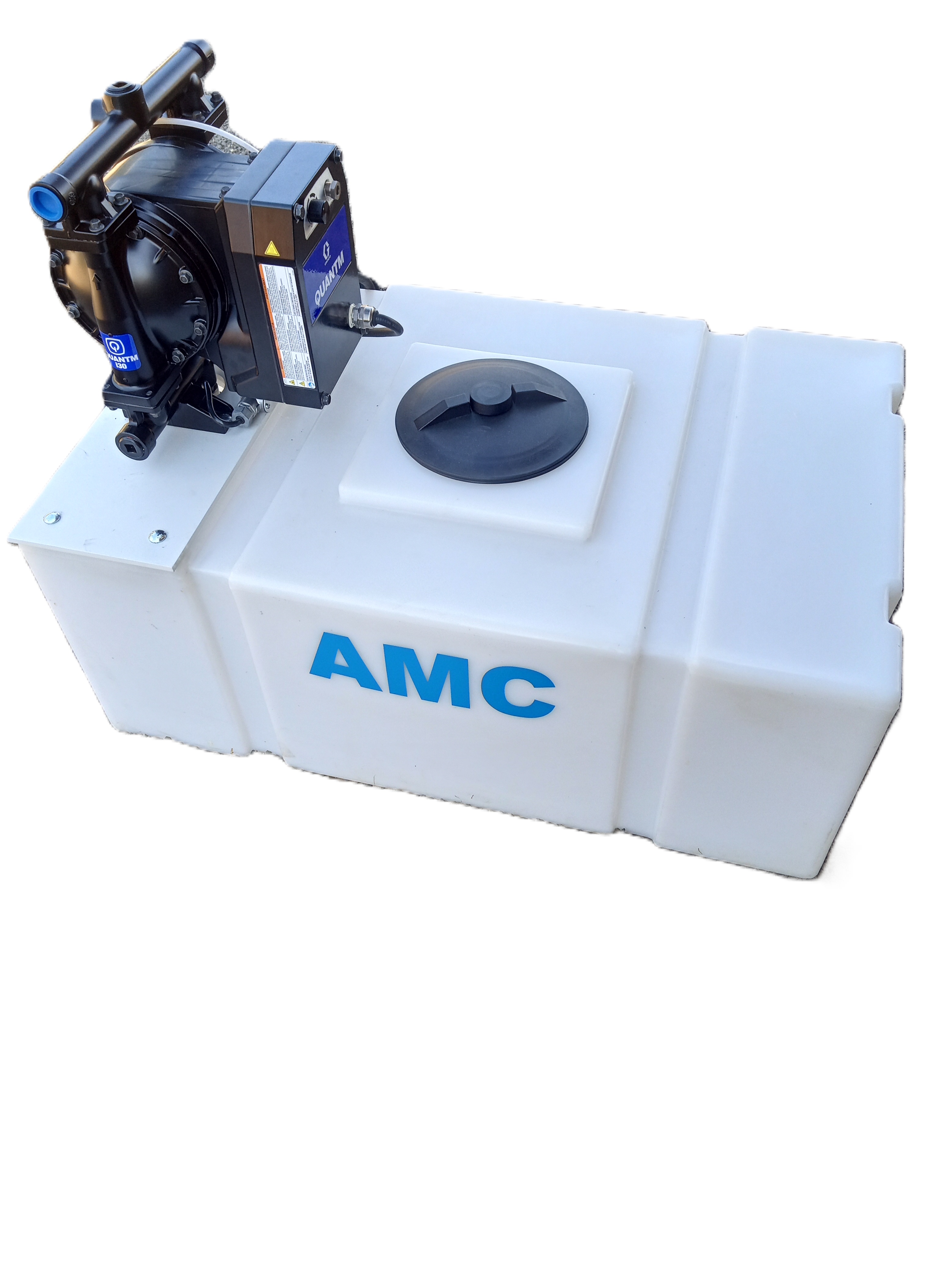

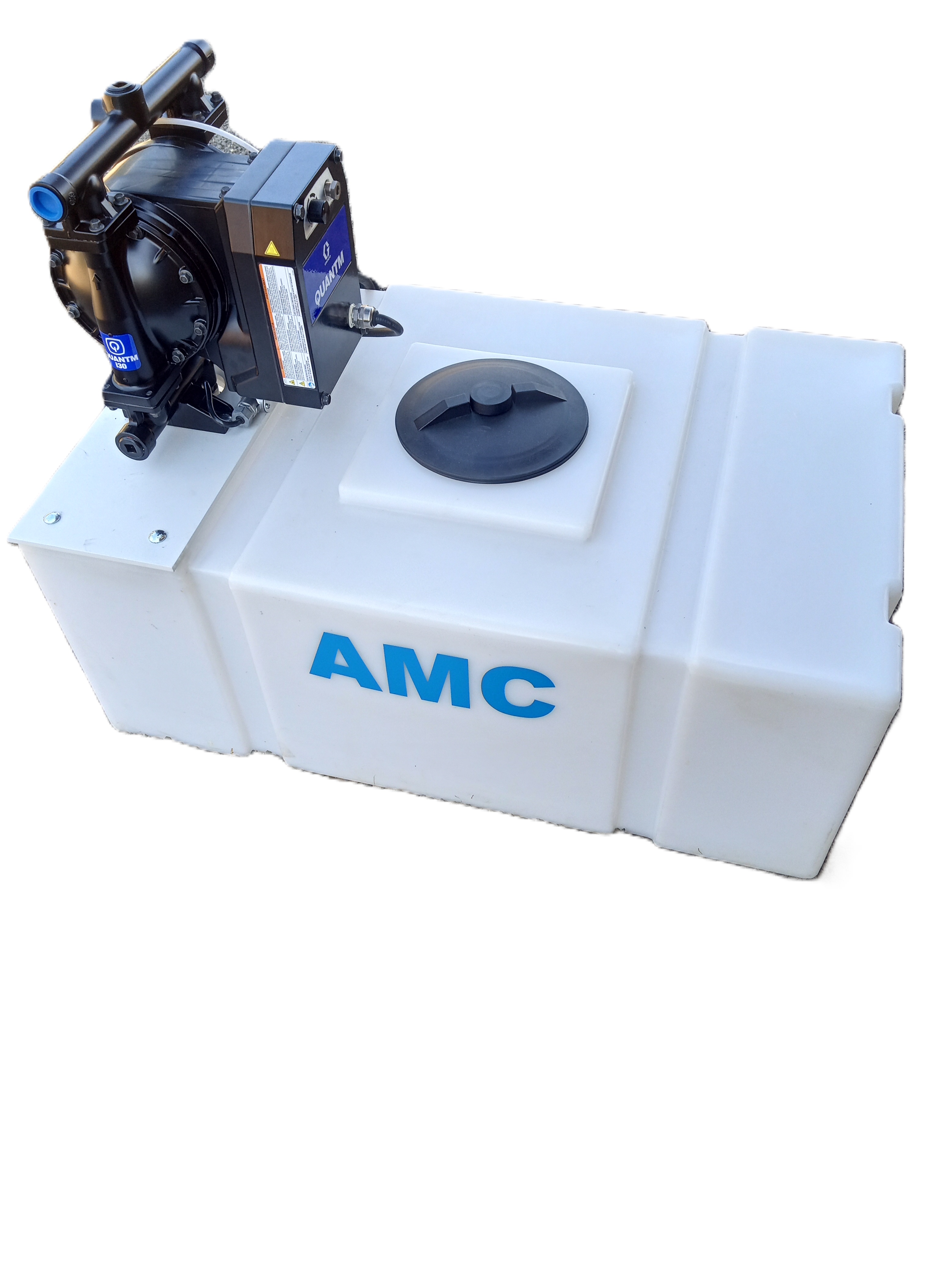

Our most popular system - versatile enough for any application. Perfect size for most compressor stations, valve sites, and general containment needs.

SCADA-compatible electric system with Class 1 Div 1 rating.

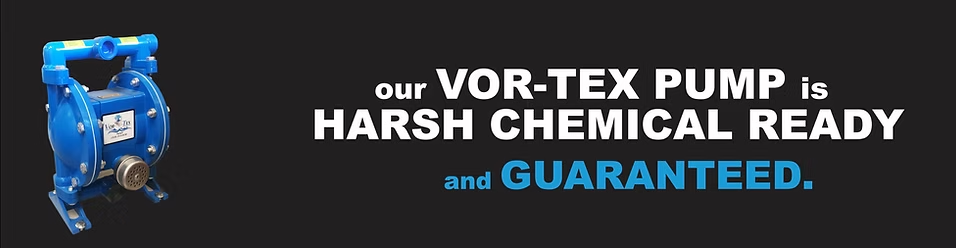

Larger capacity for sites with higher fluid volumes. Vor-Tex pneumatic pump for reliable automated operation.

Maximum capacity for high-volume applications. Custom sizes available to meet any containment requirement.

These photos show actual Enviro-Tank systems protecting facilities across the Gulf Coast

AMC Tanks (Arizona Manufacturing Company) - Your complete solution for automated spill containment.

Unmanned natural gas compression facilities with 24/7 operation needs.

Valve sites, meter stations, and pump stations along pipeline routes.

Tank batteries, wellheads, and production facilities.

Refineries, chemical plants, and processing facilities.

| Factor | Manual Pumping | Enviro-Tank System |

|---|---|---|

| Labor Cost | Thousands per month | $0/month |

| EPA Compliance | Risk between visits | 24/7 Compliant |

| Response Time | Hours to days | Immediate |

| Weather Delays | Common | None |

| Slip/Fall Risk | High liability | Eliminated |

| Weekend/Holiday | Overtime rates | Always working |

| Model | 30-Gallon | 68-Gallon Standard | 68-Gallon Electric | 210+ Gallon |

|---|---|---|---|---|

| Tank Capacity | 30 gal | 68 gal | 68 gal | 210-500+ gal |

| Pump Type | Vor-Tex Pneumatic | Vor-Tex AODD | Graco Quantum | Multiple Options |

| Power Source | Compressed Air | Compressed Air | Electric/Solar | Both Available |

| SCADA Compatible | No | No | Yes | Optional |

| Explosion Proof | Intrinsically Safe | Intrinsically Safe | Class 1 Div 1 | Both Options |

| Containment Pan | 75-gal Optional | 150-gal Standard | 150-gal Standard | Custom Sized |

Specifically engineered for the aggressive chemicals in natural gas and condensate service:

EPA penalties for spills can be severe. One incident at an unmanned site could cost more than multiple complete Enviro-Tank systems. Plus potential environmental remediation costs and reputation damage.

Contact our team for expert sizing and competitive pricing

From single compressor stations to entire pipeline systems, we've helped companies eliminate manual pumping, avoid EPA fines, and achieve true 24/7 unmanned operation. Your facility could be next.

Expert sizing, competitive quotes, and 40+ years experience

📞 (318) 353-0430

✉️ [email protected]

Homer, Louisiana | Serving Gulf Coast & Beyond